Find the Right Fit For Your Custom Industrial Insulation Systems

EXTOL PRODUCTS OVERVIEW

Extol of Ohio, Inc. since 1985, has been dedicated to providing complete industrial insulation systems custom fabricated to meet the exacting needs of process facility owners world-wide! The quality and precision of manufacture is evident in every piece. View Extol’s Specialty Fabricated Insulation Systems for Mechanical Joints, Valves, Vessels and Cladding. If you have a specific idea or application; contact us, we can make it!

Extol insulation materials are primarily cellular; thus providing exceptional insulation value, moisture resistance and longevity. We obtain the raw materials of Cellular Glass, Extruded Polystyrene, Polyisocyanurate and Phenolic foam insulation materials and fabricate pipe covering, fittings and vessel insulation shapes to order. Additionally, composite insulation systems utilizing high temperature products such as a mineral wool liner combine to expand the process temperature of the insulation system offering. Extol provides compatible coatings, adhesives, joint sealers, mastics and either a weather or vapor barrier cladding system to complete every type of application.

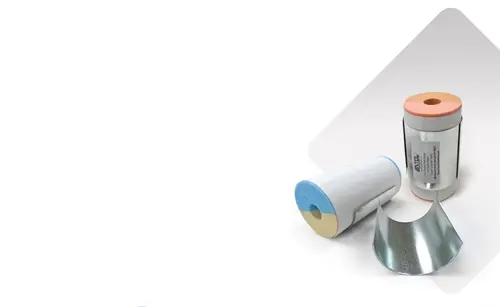

PIPE COVERING

A mainstay of Extol of Ohio, Inc. products is the fabrication of pipe covering in single or multiple layers from Cellular Glass, Polyisocyanurate, Extruded Polyisocyanurate and Phenolic closed-cell materials.

These products, each having their own exceptional R or K values, operating temperature limits, compressive strengths, dimensional stabilities properties, etc., insulate process lines that have operating temperatures from -450°F to 900°F.

Used in a variety of applications, these durable products offer thermal performance, fire protection and/or moisture resistance in both commercial and industrial applications. Pipe covering is supplied plain, coated or with various moisture or vapor retarder jacket systems.

CURVED SIDEWALL SEGMENTS

Curved sidewall segments fit the exact curvature and are supplied for large diameter pipes over 20 inches and for vessels or equipment of all sizes. Available in single or multiple layers from Cellular Glass, Polyisocyanurate, Extruded Polystyrene and Phenolic closed-cell materials, they can be used in a range of applications such as below ambient, ammonia or cryogenic systems. Additionally, they are found on tank shells for the food/beverage, chemical/petro-chemical, pharmaceutical processing systems, commercial or industrial piping, and more. These products, each having their own exceptional R or K values, operating temperature limits, compressive strengths, dimensional stabilities properties, etc., insulate systems that operate from -450°F to 900°F. These durable products offer thermal performance, fire protection and/or moisture resistance in both commercial and industrial applications.

INSULATED SUPPORTS

Extol Insulated supports are designed for use in the industrial and commercial insulation industry. Our supports are easy to specify, order and install and are available for all types of piping systems. Extol Insulated Supports meet or exceeds all industry standards. From the typical support system to the most complex applications, our products fit and perform. Understanding that when it comes to engineering, one size does not fit all. Extol Insulated Supports are designed and fabricated to fit the application on a specific project. Customized to your specifications, fabricated to fit your pipe. We collect design information that is required to calculate the support that is required for your project.

MECHANICAL JOINT INSULATION

Un-insulated fittings, valves and couplings create excessive heat gains or loss. Extol’s Mechanical Joints Insulation will equip your system with continuous process control. Call us for assistance with an Energy Analysis of your specific application. Our quality, precision cut 2-piece insulation mechanical joint insulation covers fit the contour of the most complex shapes. This reduces installation time and saves you money. To provide a for indoor insulation, we have teamed with manufactures to provide heavy duty (.030in.) PVC fitting covers. Through our continuing development efforts we now provide custom matching PVC covers in all colors for 90’s, 45’s, Y’s and couplings that fit.

METAL FITTING, VALVE & VESSEL HEAD COVERS

When pressed metal covers are not available, Extol of Ohio, Inc. factory fabricated Metal Gore Fitting Insulation Covers are the answer. Eliminating the need for field fabrication, the result is reduced labor costs while ensuring a proper fit. Made in segmental form to conform to exacting ASTM C-450 specifications we provide 90 and 45 degree elbows, tees, end caps, valve covers and head or vessel end coverings from smooth or stucco embossed aluminum or stainless steel materials to protect the insulation from weather and mechanical abuse.

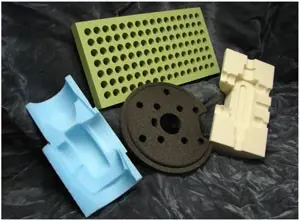

OEM PRODUCTS

State of the Art fabrication equipment allows EXTOL of OHIO, Inc to precision cut insulation shapes, fabricated to your exact specifications. We use cellular, rigid materials to supply constant thermal performance plus moisture and corrosion resistance. Through our continuing developmental efforts, we are able to create insulation shapes for small prototype projects as well as mass production runs. Insulation materials include: Cellular Glass, Extruded Polystyrene, Phenolic Foam, Polyisocyanurate and High Temperature Polyisocyanurate.

PRECISION ENGINEERED HEAD SEGMENTS

Prevent excessive heat loss or heat gain with Extol of Ohio’s thermally efficient “Precision Engineered Head Segments.” Fabricated to precisely fit the exact curvature of the surface, the heads are numbered and supplied for installation in courses around a center. Costly field fabrication from flat or curved blocks is eliminated and installation is completed in minimum time so labor expenses are reduced. Extol of Ohio provides an “Entire Insulation System” for your application. Complete your vessel head insulation with our pre-formed curved sidewall segments, beveled lags, weather and vapor retarder cladding, mastics, caulkings, joint sealers, bands and springs that are compatible with each insulation product.

SHIELDS

Extol Fabricated Shields are designed for use in the industrial and commercial insulation industry. Galvanized G-90 carbon steel or T304-2B stainless-steel shields, in gauges from 24ga to 10ga, are easy to specify, order and install. They are fabricated to fit standard ASTM C-585 insulation lengths and diameters. From the average application to the most complex, our shields fit and perform. Extol Fabricated shield diameters range from 1.5” through 40” with various lengths available. Some shields are ribbed while adding strength, they also help to prevent ‘creeping’ with movement of the pipe. Ends are flared to reduce interference with the insulation system.

VALVE INSULATION

Un-insulated valves and flanges create excessive heat gains for your refrigerant and low temperature process piping. Extol has formed alliances with the most recognizable valve manufacturer names in the industry and our quality, precision cut 2-piece insulation valves fit the contour of the most complex valve shapes providing your system with continuous process control. This reduces installation time and saves you money. To provide a USDA accepted system for indoor insulation, we have teamed with PIC Plastics to provide heavy duty (.030″) PVC Valve covers to fit T-Shaped valves, Y-Shaped Valves and Control Valves with Strainers. All colors are available. Through our continuing development efforts we now provide custom matching PVC or Metal Covers for the non-standard shapes found with valves, valve groupings, control valves with strainers and for non-standard Y-Shapes for both indoor and outdoor roof applications.

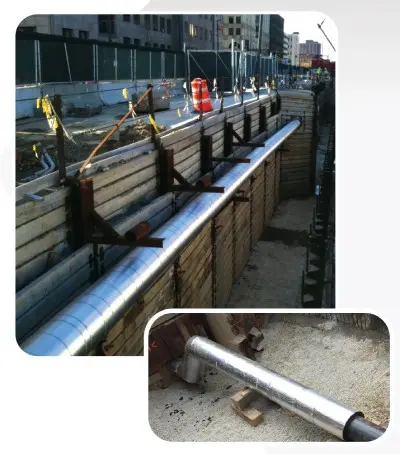

WATERWORKS APPLICATIONS

Extol of Ohio, Inc. Insulation systems for Waterworks applications are fabricated for pipe and tank systems that carry Water, Storm water and for Sanitary sewer systems. They are designed to work in the harshest environments. Extol of Ohio, Inc. has been the leader in fabrication of closed cellular rigid insulation systems for refrigeration, chilled water, steam process, oil and gas as well as Waterworks applications for over 35 years. We are known around the globe for our quality and service. Our products are made from the very best materials. Our technical service is second to none. We put our reputation into every product that we make.